Fault detection and diagnostics (FDD) is the process of identifying and analyzing malfunctions or failures within a building’s systems to detect and diagnose faults as early as possible. Early detection minimizes the impacts of downtimes, prevents future failures, and improves overall system performance. FDD is crucial for maintaining the reliability and efficiency of a building’s HVAC system.

How Do FDD Systems Work?

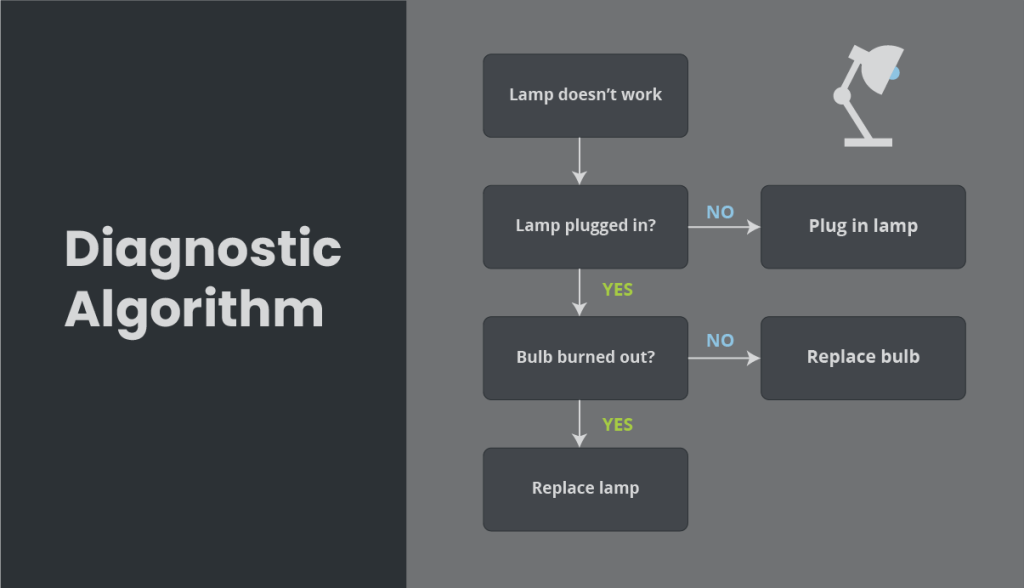

FDD is typically achieved using sensors, monitoring systems, and diagnostic algorithms. These tools work together to continuously monitor the performance of the system and detect any abnormal patterns that may indicate a fault. The diagnostic algorithms then analyze the collected to identify the specific fault and provide recommendations for how to address it.

One of the key benefits of FDD is that organizations can proactively identify and address potential issues before they lead to costly downtime or equipment damage. Too often, building owners, maintenance staff, and systems integrators work within a reactionary model, which often follows these steps:

- BMS alarm sounds for a VAV

- VAV unit inspected

- Maintenance request created

- Repair or replacement made

This reactionary model works but is inefficient. How long was the VAV malfunctioning before the alarm? How much energy was lost before? How long as it been affecting occupant comfort levels? How much time is required for all steps? How much energy, money, and comfort are sacrificed during downtime? These questions represent the issues inherent in the reactionary model.

FDD sees the problem before the inefficiencies start by using analyzing data from fault trends to predict failures before the actual alarm sounds. If a VAV is consistently running below specification, FDD can flag the activity as consistent with a failing terminal unit. That gives maintenance longer lead times and shortens downtimes.

FDD Systems Lower Energy Costs

With the growing emphasis on energy efficiency, FDD is becoming increasingly important as a tool for improving overall system performance and reducing energy consumption. Recent studies show that between 5% – 30% of commercial building energy is wasted due to problems associated with controls (Deshmukh 2018). So, FDD offers a massive opportunity to increase energy savings by finding faults faster.

One of the most common types of FDD systems used in buildings is Building Energy Management Systems or BEMS. These computer-based systems monitor and control the HVAC, lighting, and other building systems to optimize energy efficiency. BEMS often use temperature sensors to monitor the performance of an HVAC system and detect when the system is not working as efficiently as it should. The diagnostic algorithms then analyze this data and identify the specific problem, such as a clogged filter or malfunctioning compressor.

Predictive Analytics

Another important aspect of FDD is the use of predictive analytics. Predictive analytics uses historical data and statistical models to predict when a system is likely to fail. This enables building operators and maintenance staff to take proactive measures to address potential issues before they lead to costly downtime or equipment damage. Predictive analytics can be used in a wide range of systems, including industrial equipment, vehicles, and even wind turbines.

Furthermore, the use of predictive analytics can enable organizations to take proactive measures to address potential issues before they lead to a complete system failure.

Improving System Performance

While FDD is typically associated with detecting and diagnosing equipment failures, building operators can use it to improve system performance. By identifying and addressing inefficiencies in a system, organizations can improve overall system performance and reduce energy consumption. For example, an FDD system in an HVAC system might identify that the system is running at a higher temperature than necessary, resulting in increased energy consumption. By addressing this issue, the organization can reduce energy consumption and improve overall system performance.

In conclusion, FDD is an important tool for maintaining the reliability and efficiency of various systems. By detecting and diagnosing faults early on, organizations can take steps to address the problem before it leads to costly downtime or equipment damage.